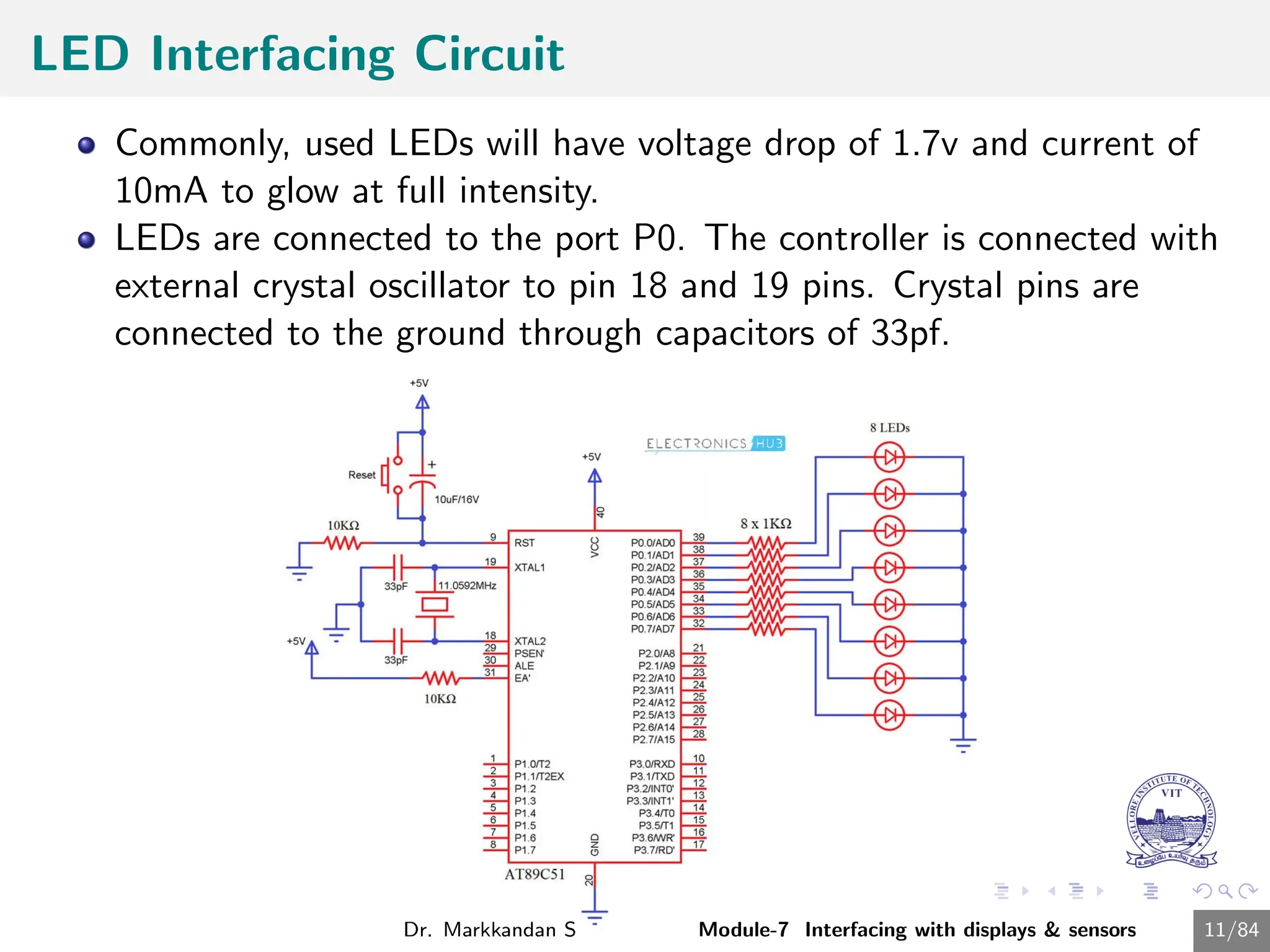

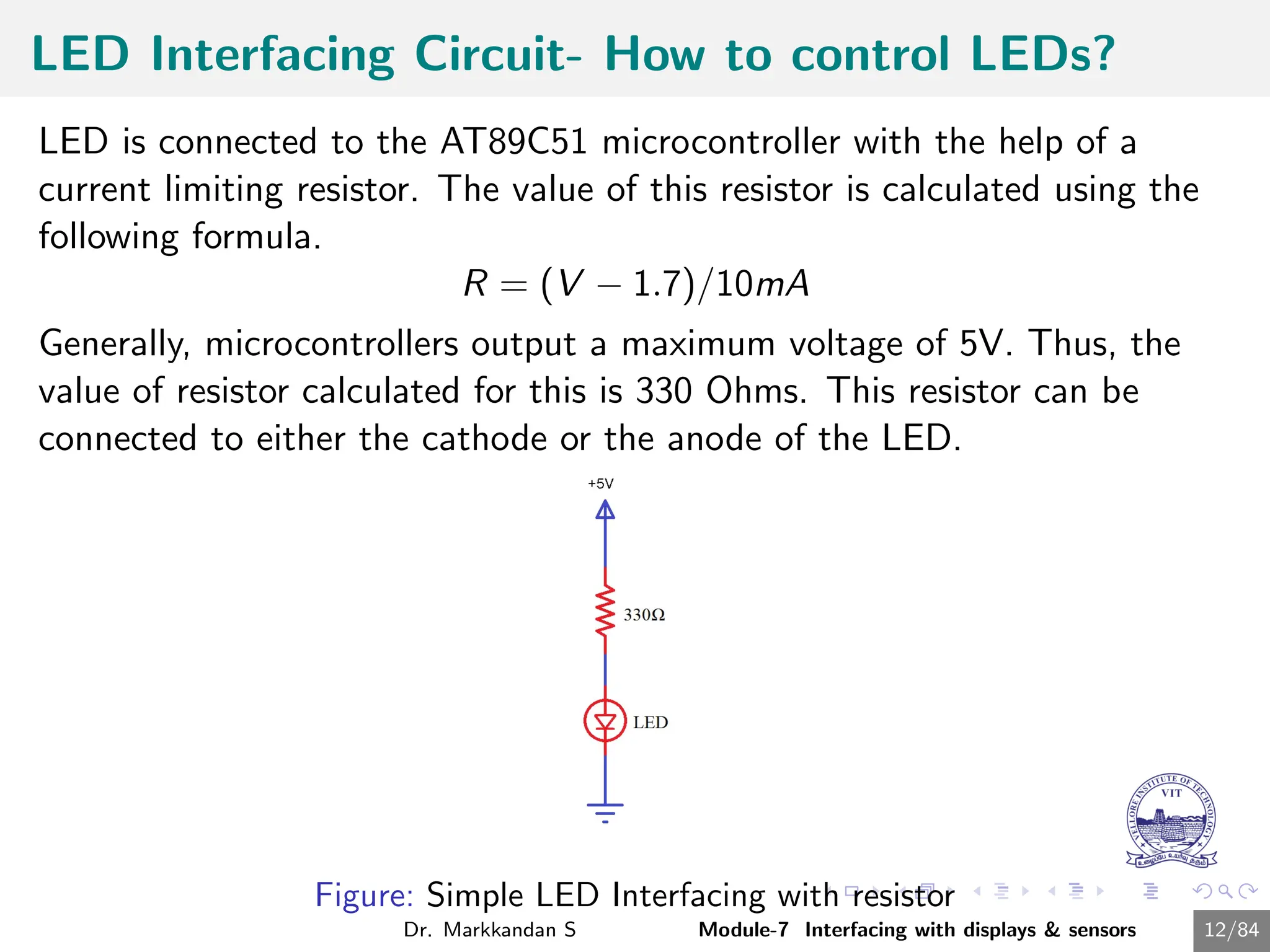

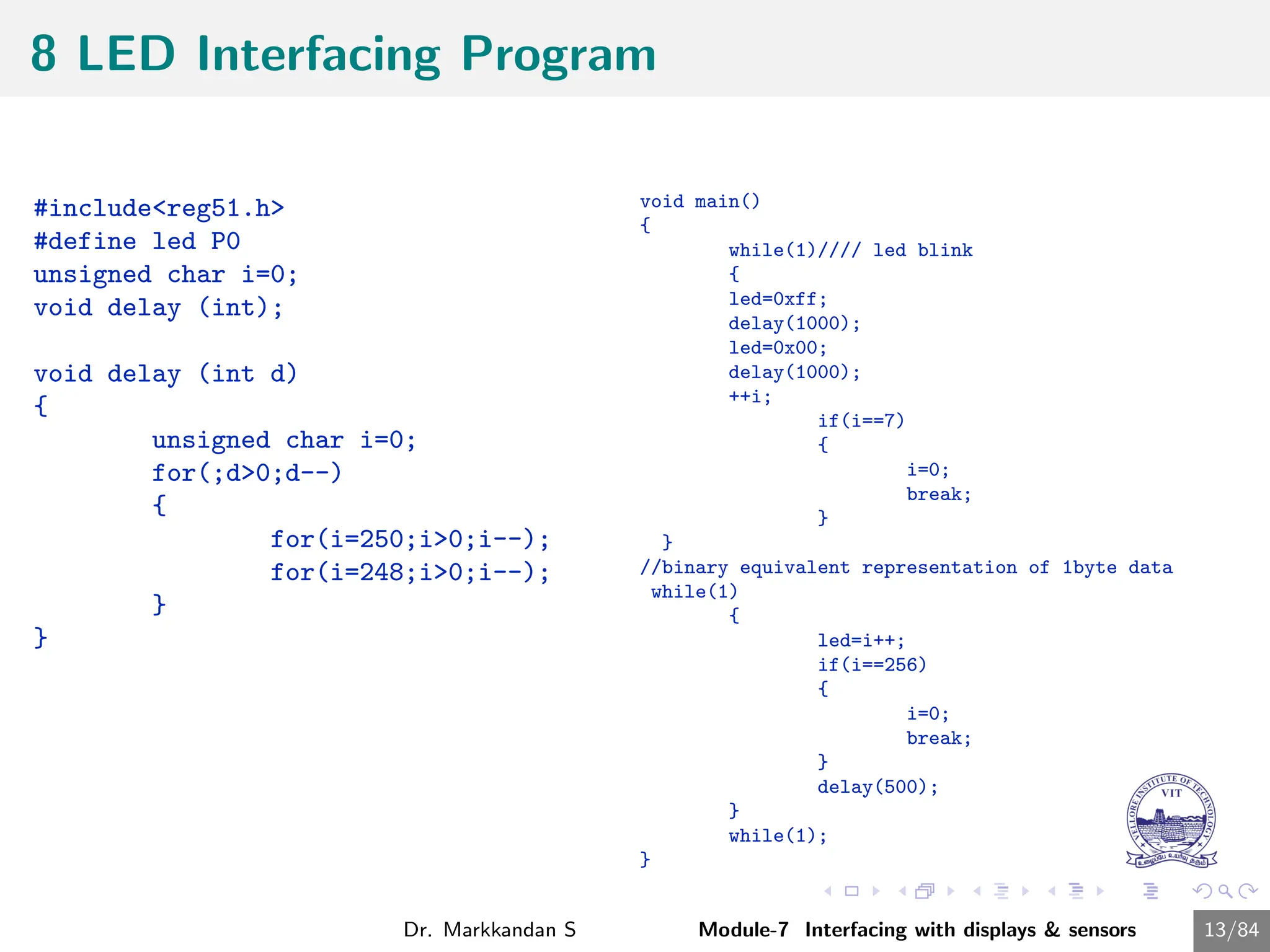

The document provides a comprehensive overview of interfacing displays and sensors in embedded systems, detailing topics such as LED, seven-segment display, and LCD interfacing. It covers the definition, importance, and basic concepts of interfacing, including signal levels and control techniques. Additionally, it includes sample codes and descriptions for interfacing various components, emphasizing the operational modes and commands for LCDs.

![Sample Seven Segment Display Program

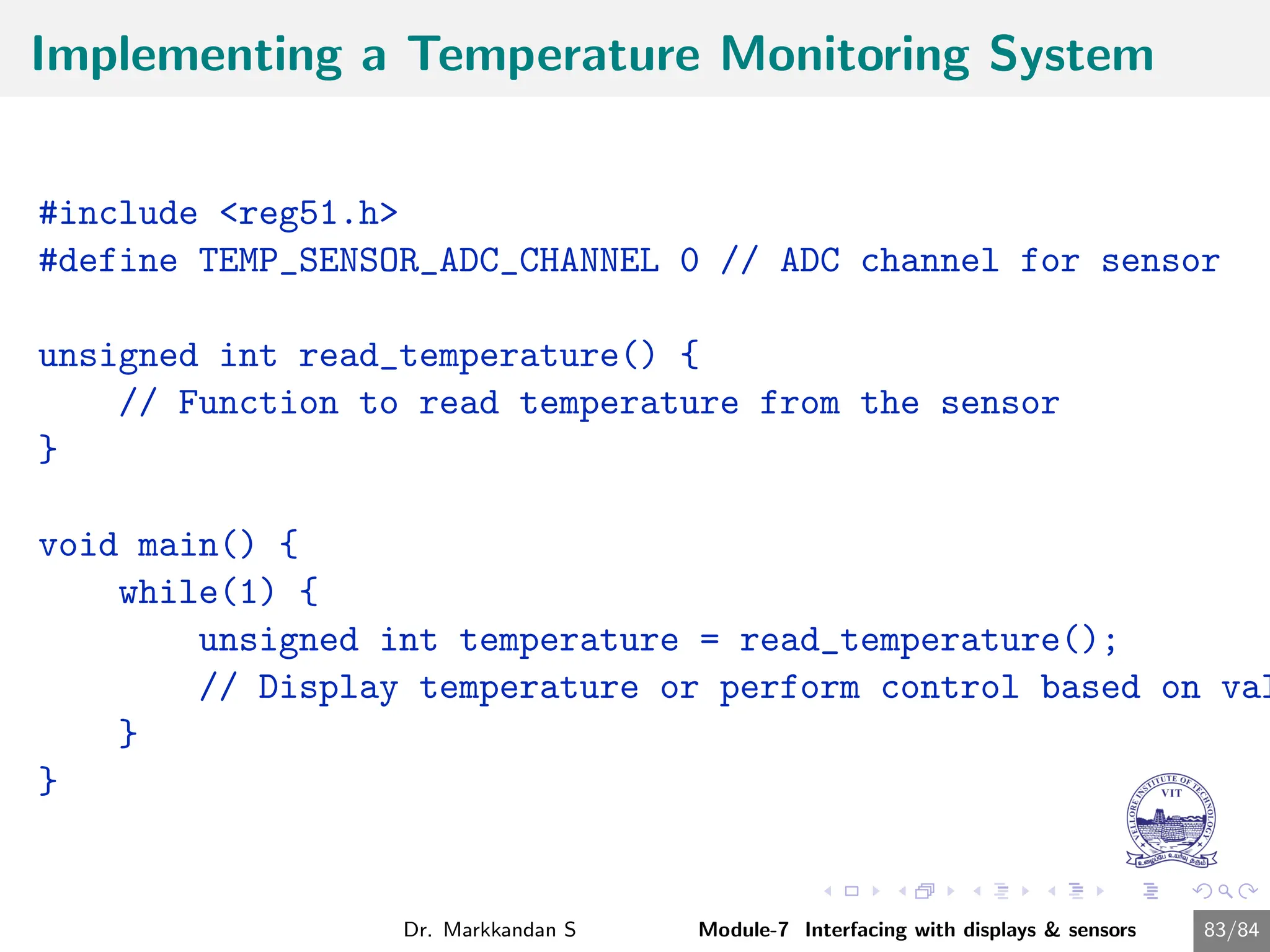

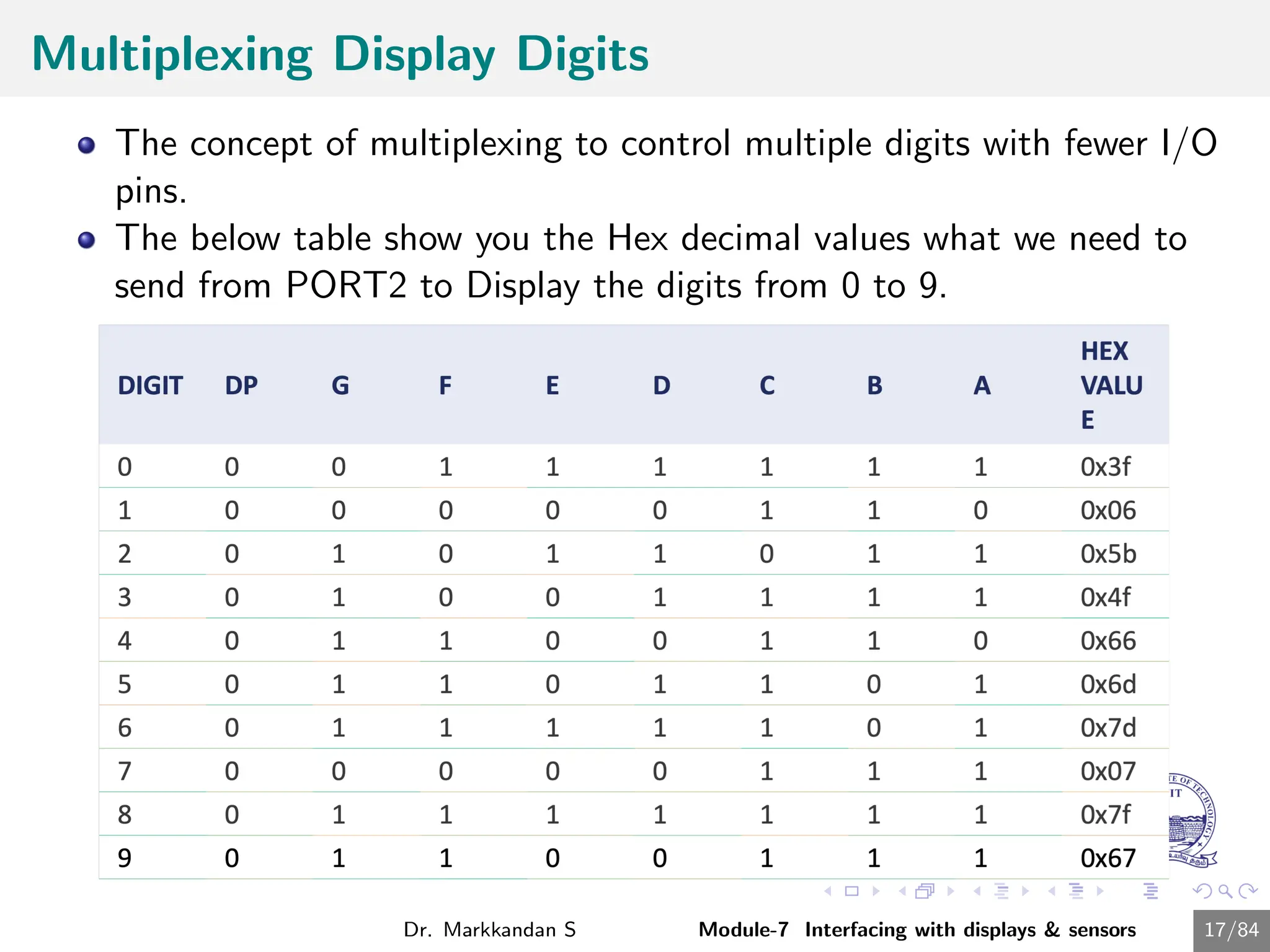

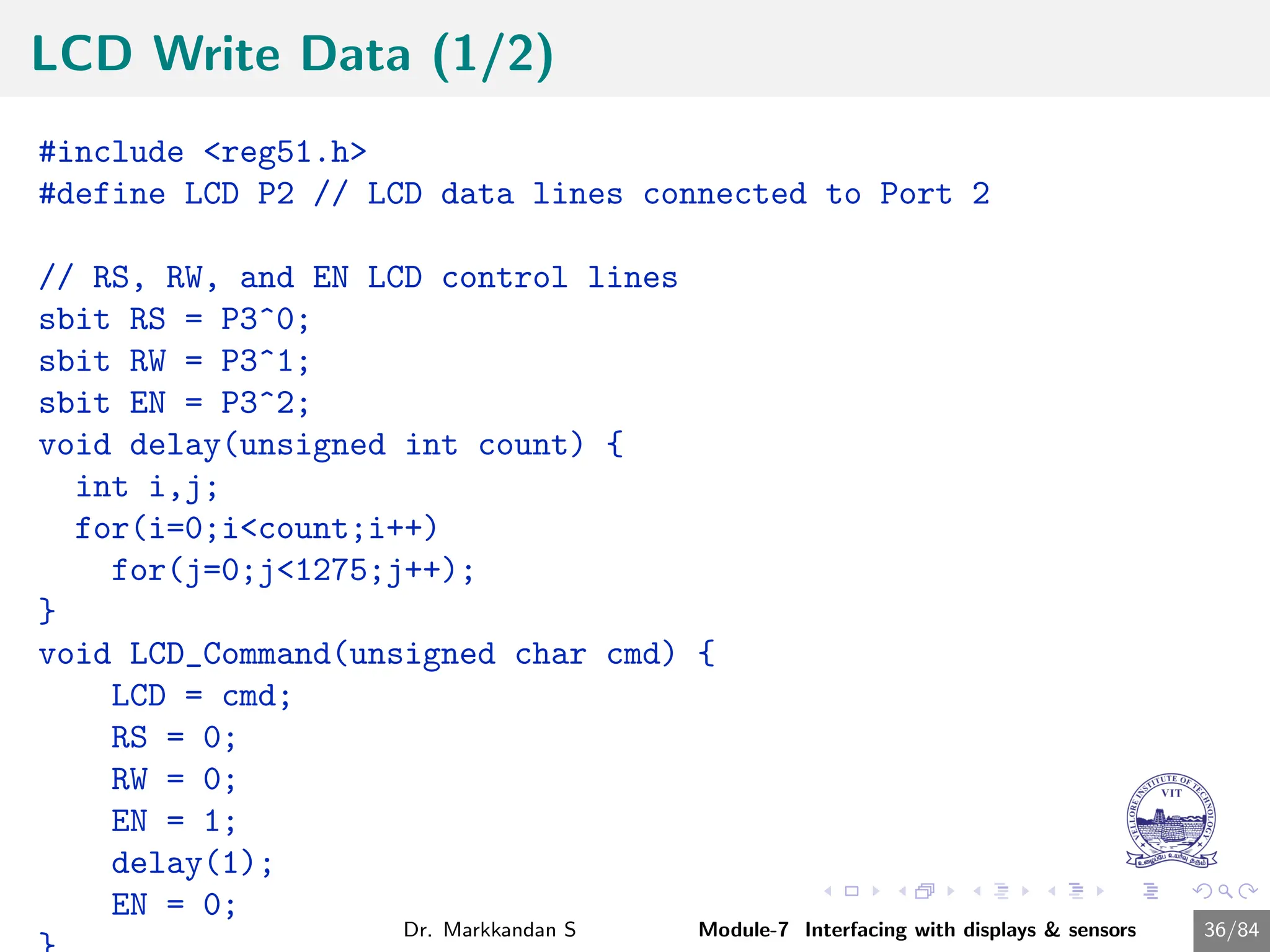

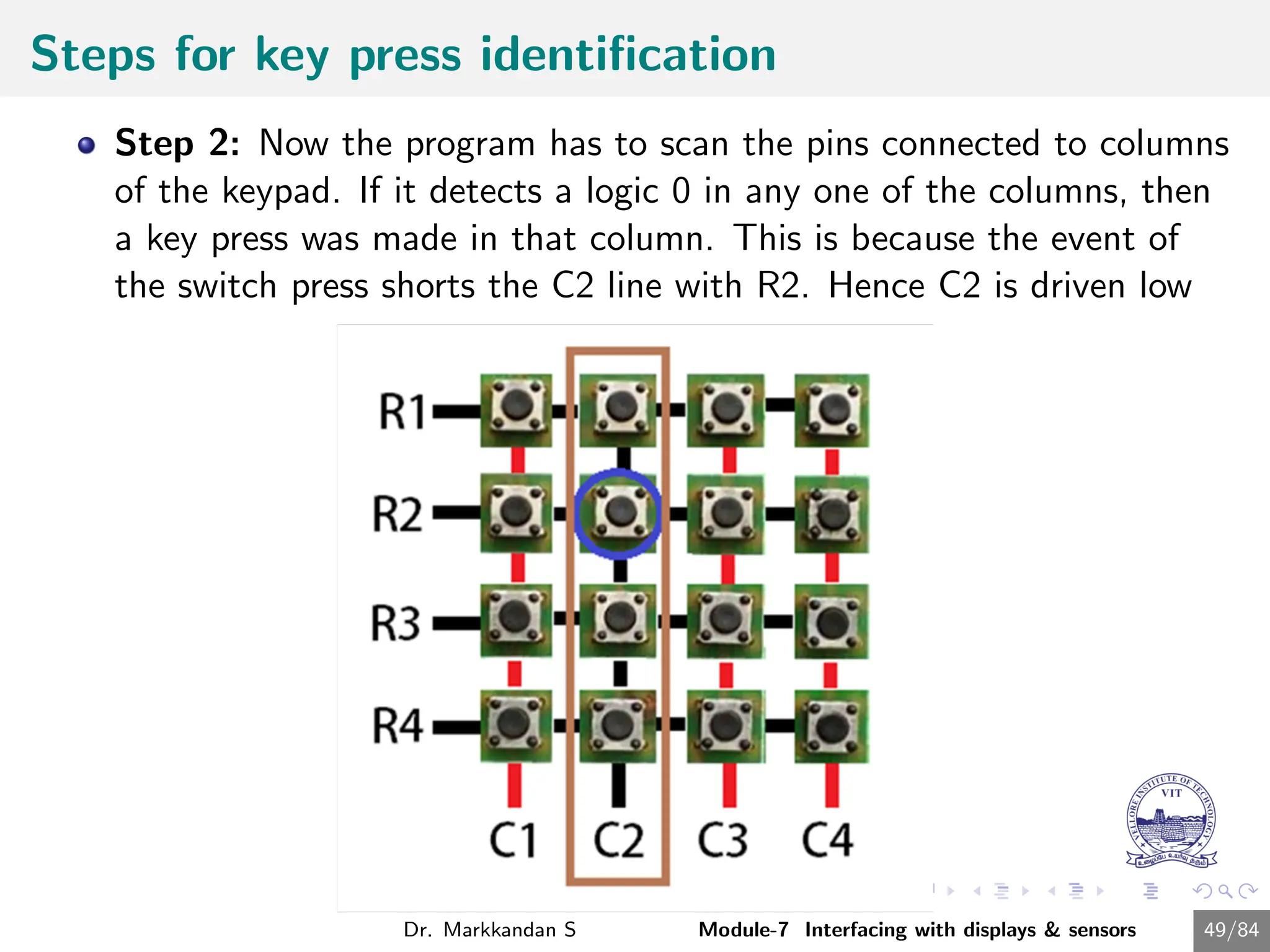

1 First initialize all the segment hex values of the digits in an array.

unsigned char

arr[10]=0x3f,0x06,0x5b,0x4f,0x66,0x6d,0x7d,0x07,0x7f,0x67;

2 Now take for loop and assign array values to the PORT2 with some

time delay.

for (i=0;i<10;i++)

{

P2=arr[i];

delay_ms(500);

}

Dr. Markkandan S Module-7 Interfacing with displays & sensors 18/84](https://image.slidesharecdn.com/embeddedcmodule7-240716034846-94726bf2/75/Embedded-C-Programming-Module-7-Presentation-18-2048.jpg)

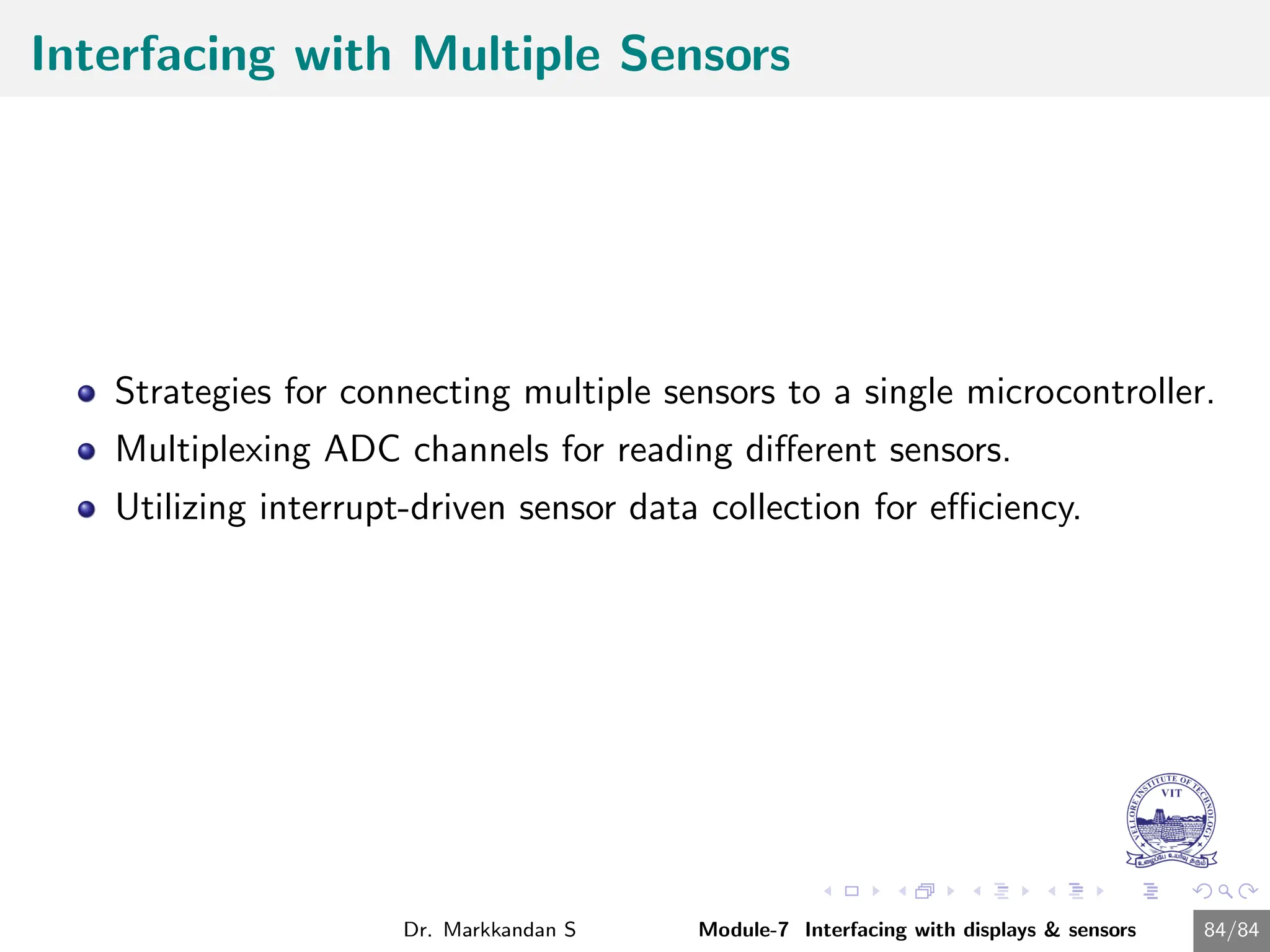

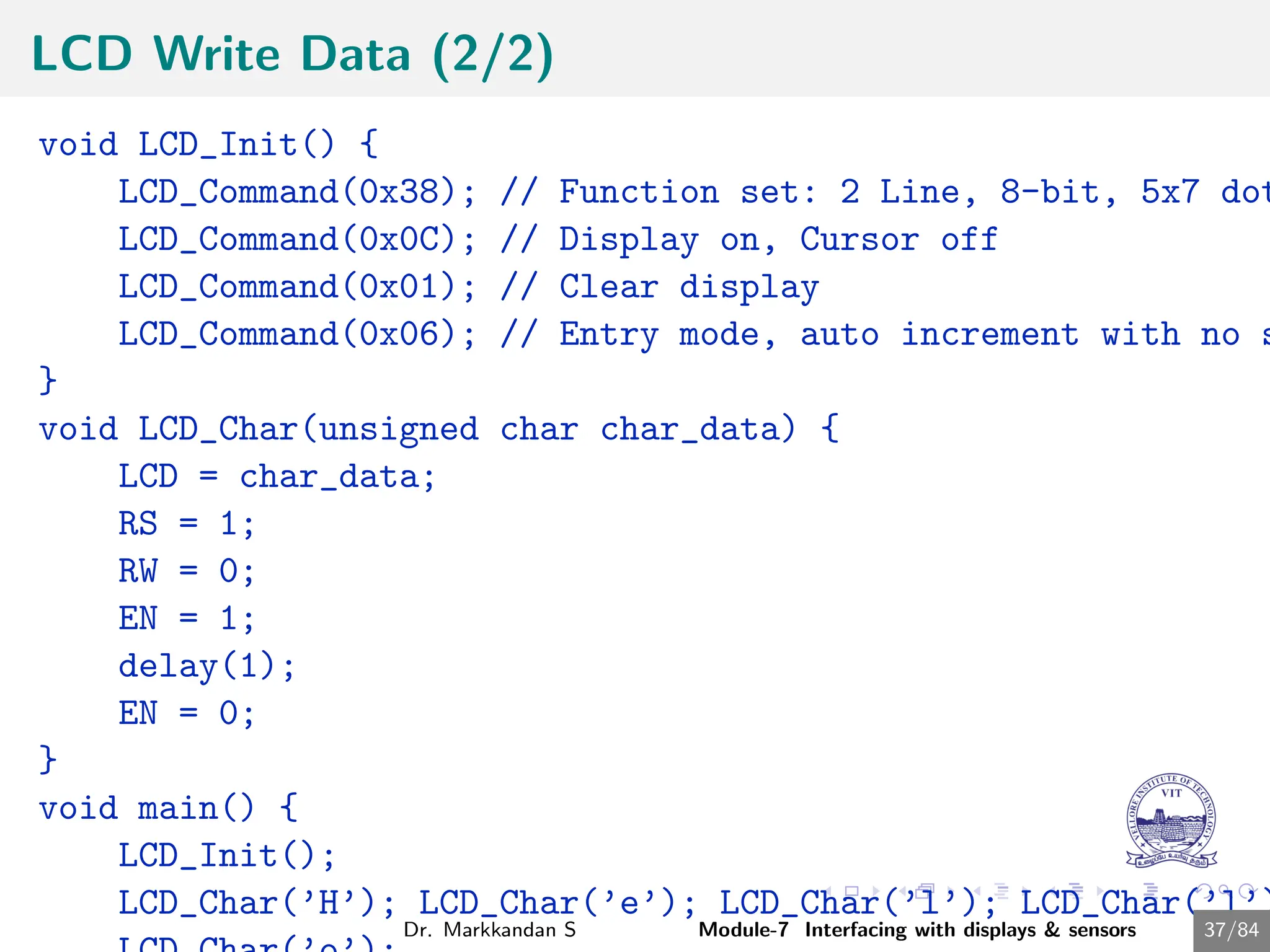

![Custom Character |and smiley in LCD(2/3)

// LCD initialization function

void LCD_Init() {

LCD_Command(0x38); // Function set: 2 Line, 8-bit, 5x7 dots

LCD_Command(0x0C); // Display on, Cursor off

LCD_Command(0x01); // Clear display

LCD_Command(0x06); // Entry mode, auto increment with no shift

}

// Function to display a single character

void LCD_Char(unsigned char char_data) {

LCD = char_data;

RS = 1;

RW = 0;

EN = 1;

delay(1);

EN = 0;

}

// Function to create custom characters

void LCD_CustomChar(unsigned char loc, unsigned char *msg) {

unsigned char i;

if(loc<8) {

LCD_Command(0x40 + (loc*8)); // Command 0x40 and onwards forces the device to point CGRAM address

for(i=0; i<8; i++) // Write 8 byte for generation of 1 character

LCD_Char(msg[i]);

}

}

Dr. Markkandan S Module-7 Interfacing with displays & sensors 39/84](https://image.slidesharecdn.com/embeddedcmodule7-240716034846-94726bf2/75/Embedded-C-Programming-Module-7-Presentation-39-2048.jpg)

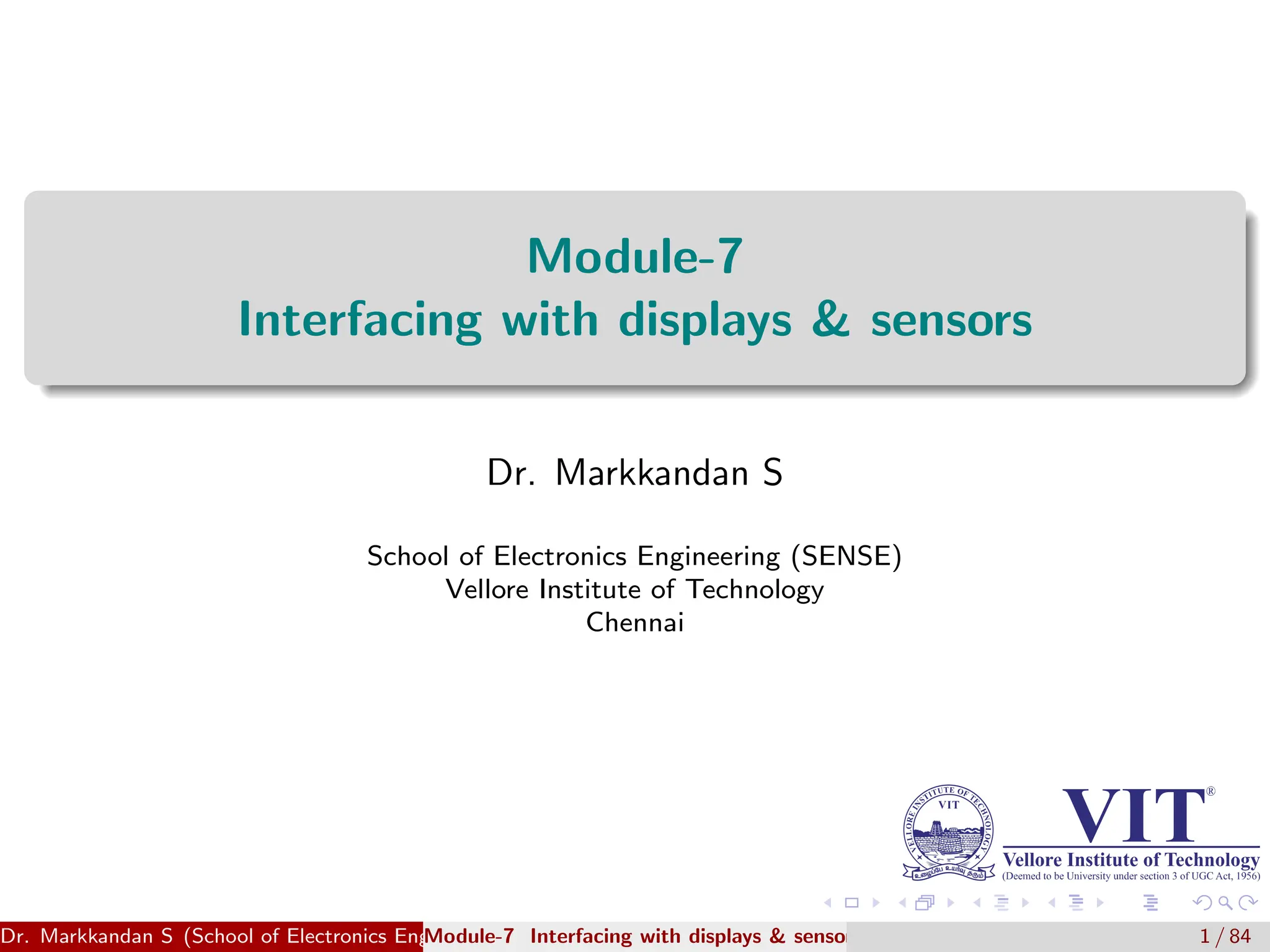

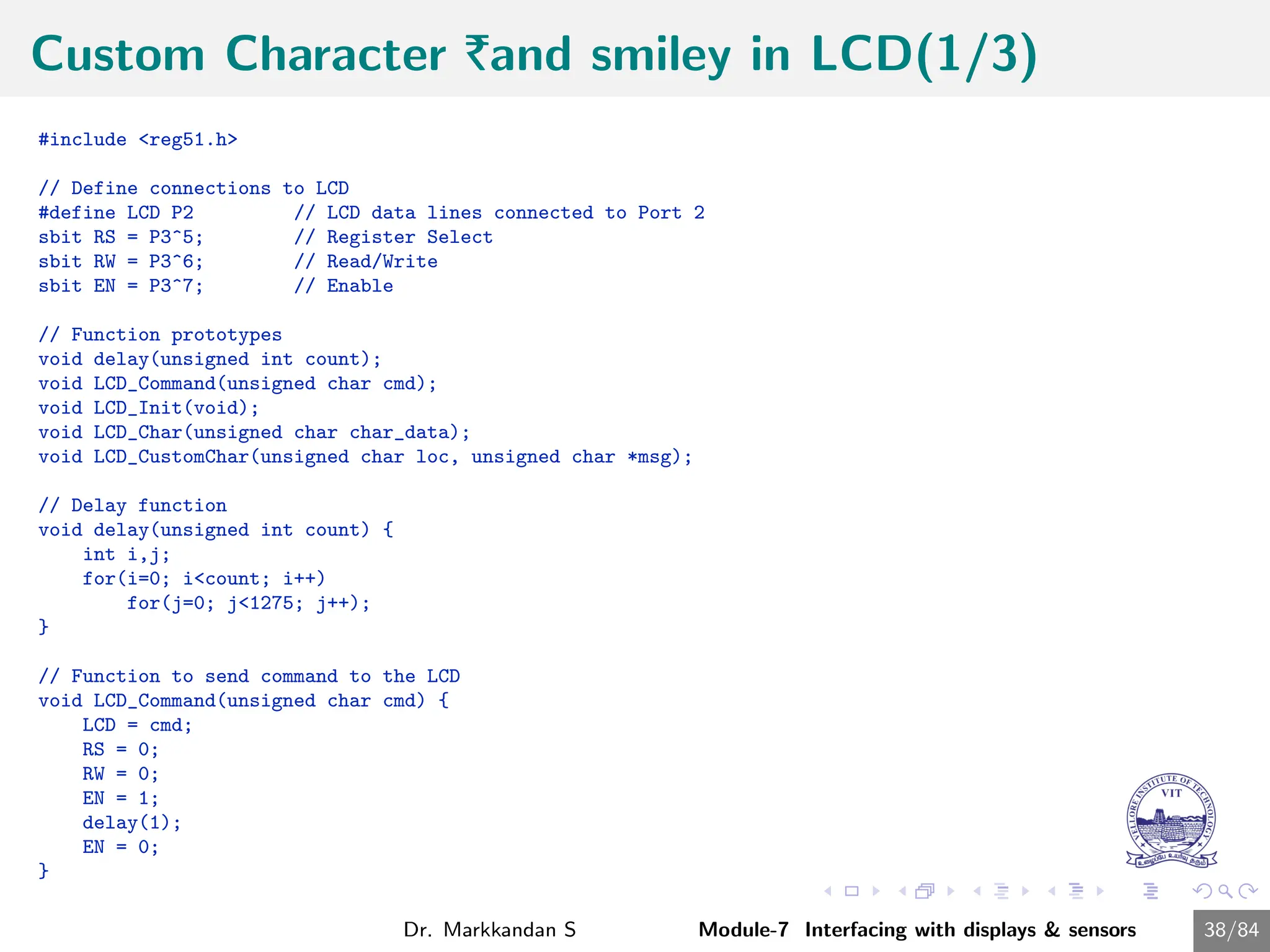

![Custom Character |and smiley in LCD(3/3)

void main() {

unsigned char Smiley[8] = {0x00, 0x00, 0x0A, 0x00, 0x11, 0x0E, 0

unsigned char Rupee[8] = {0x05, 0x07, 0x05, 0x1F, 0x05, 0x07, 0x

LCD_Init(); // Initialize LCD

// Create custom characters

LCD_CustomChar(0, Smiley);

LCD_CustomChar(1, Rupee);

// Display custom characters

LCD_Command(0x80); // Move cursor to the beginning of first lin

LCD_Char(0); // Display Smiley

LCD_Char(1); // Display Rupee symbol

while(1); // Infinite loop to keep displaying the char

}

Dr. Markkandan S Module-7 Interfacing with displays & sensors 40/84](https://image.slidesharecdn.com/embeddedcmodule7-240716034846-94726bf2/75/Embedded-C-Programming-Module-7-Presentation-40-2048.jpg)

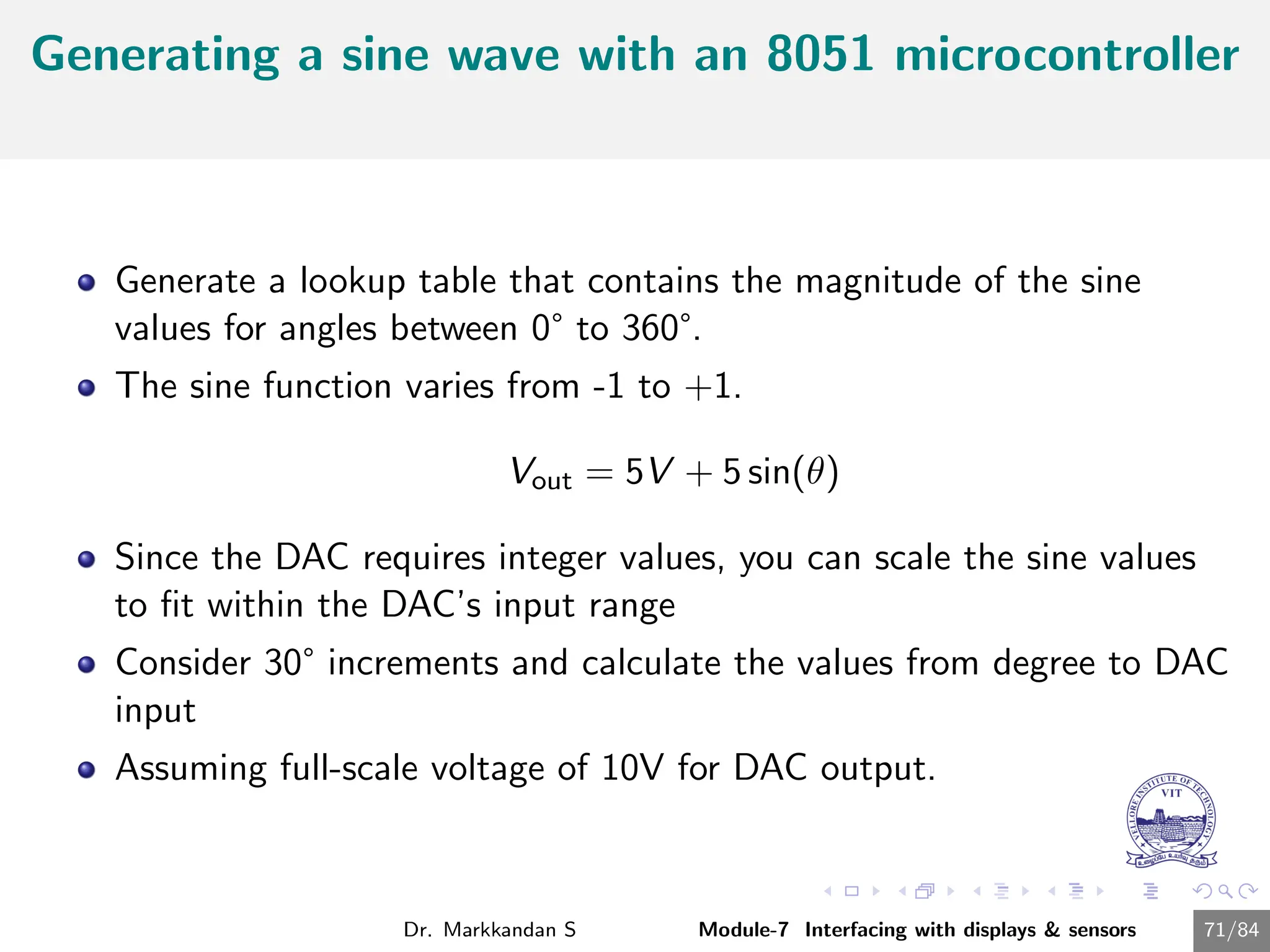

![Generating a sine wave using DAC in 8051

Programme

#includereg51.h

sfr DAC = 0x80; //Port P0 address

void main(){

int sin_value[12] = {128,192,238,255,238,192,128,64,17,

int i;

while(1){

//infinite loop for LED blinking

for(i = 0; i12; i++){

DAC = sin_value[i];

}

}

}

Dr. Markkandan S Module-7 Interfacing with displays sensors 73/84](https://image.slidesharecdn.com/embeddedcmodule7-240716034846-94726bf2/75/Embedded-C-Programming-Module-7-Presentation-74-2048.jpg)

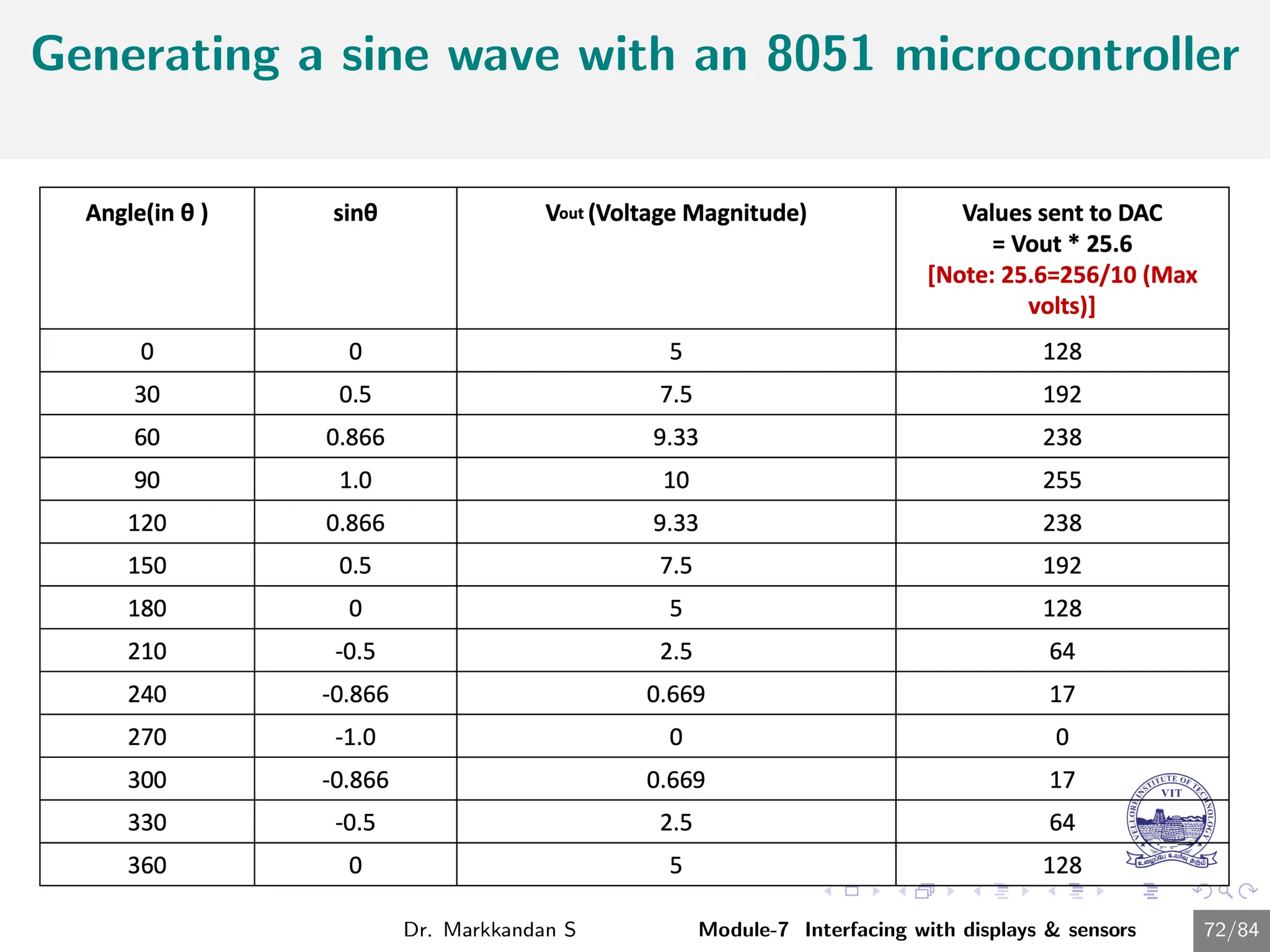

![Sine wave generation for every 10 degree

#includereg51.h

int main()

{

int j;

int c[37]={128,150,172,192,210,226,239,248,254,255,254,248,

239,226,210,192,172,150,128,106,84,64,46,30,17,8,2,0,2,8,17,

30,46,64,84,106,128};

while(1)

{

for(j=0;j36;j++)

{

P1=c[j];

}

P1=128;

}

}

Dr. Markkandan S Module-7 Interfacing with displays sensors 74/84](https://image.slidesharecdn.com/embeddedcmodule7-240716034846-94726bf2/75/Embedded-C-Programming-Module-7-Presentation-75-2048.jpg)