Advantages and disadvantages of industrial automation

Today I am going to talk about some of the advantages and disadvantages of industrial automation. Firstly, lets

define what automation is. By definition automation is the use of control systems such as programable logic

controllers to control industrial machinery and processes, reducing the need for human intervention. Let’s

take this closed loop control system as an example. The process here is controlled by a computer and a PLC

which receive input signals from sensors that measure output variables of the process. The controller than

compares the actual output of the process with the desired output of the system and sends a signal to the

actuators so that the desired setpoint is maintained.

These days more and more industries start using automation every day. But as every other technology

automation has both pros and cons.

Let’s start with advantages first.

The most obvious advantage of automation is increase in production capacity. Automation

increases your production capacity as machines can be set to work 24/7 unmanned.

Automated machinery can also typically run faster and produce more accurately made products

with fewer defects.

Another advantage of automation is consistency in product quality. Of course there are workers

who have been doing the same repetitive tasks for years and are really skilled in those

particular tasks. But despite that, robots and automated machinery can do any repetitive work

much faster and more eficiently than any human. Automated systems typically perform

the manufacturing process with less variability than human workers, because unlike humans,

automated machinery doesn‘t get tired or lose it‘s focus.

Furthermore, automated inspection systems can be installed at the end of a manual or

automated production line. They use sensors and vision systems to automatically check

products for defects and compliance with specification. This enables faulty products to be

rejected, eliminating defects and costly product recalls. Such a task would be mentally

exhausting and mind-numbingly repetitive for a human worker.

Another benefit of automation is the reduction in the number of hours worked on average per

week by factory workers. In the start of the 20th century the average workweek was

approximately 70 hours. This has gradually been reduced to a standard workweek in of about

40 hours. Mechanization and automation have played a significant role in this reduction.

Increased safety – Manufacturing has always posed risks to factory workers, as it involves large

heavy machines with moving parts capable of injuring nearby workers by accident. Automated

systems can respond to potential problems by immediately stopping the machinery, without

depending on any human input. For example, the German company Bosch’s mobility solutions

plant in Mexico began using photoelectric light curtains around a machine that installs needle

bearings in engine shafts in 2014. This automatic safety system shuts the machine down right

away whenever they are interrupted by an object or a human worker.

However, despite all of the pros, automation also has some disadvantages.

Firstly, the initial costs of automating a single process, not even talking about the whole factory

can be realy high. The automation of a new product or the construction of a new plant requires

a huge initial investment compared to the unit cost of the product. Even machinery for which

the development cost has already been recovered is expensive in terms of hardware and labor.

Also, there can be several unpredictable costs that may exceed the actual cost saved by the

automation itself. Some of these costs could include research and development costs of

� automating a process, preventative maintenance costs, and the cost of training employees to

operate automated machines.

Moreover, companies that decide to automate the processes might need to hire more

engineers or technicians. Servicing and maintaining the automated system in proper working

order can be difficult. Failure to maintain the automatic system properly might ultimately result

in lost production or products of poor quality being produced.

It is true that with the introduction of automation there are some jobs that may become

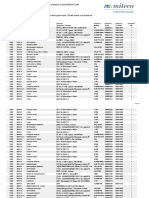

redundant. As we can see from this survey conducted by The Organisation for Economic Co-

operation and Development in 2013 the sector that will be the most influenced by automation

will be food preparation. By the estimates more than half of all workers will be automated in

construction, cleaning, driving, agricultural labour, garment manufacturing and personal service

fields.

Another disadvantage is the lack of flexibility in terms of the different possible production as

compared with a manual system. Automation can be grouped in three categories: fixed,

programmable and flexible automation. Fixed automation is only suitable for products that are

made in large volumes. This is because the programmed commands are contained in the

machines in the form of cams, gears, wiring, and other hardware that is not easily changed over

from one product style to another. Programmable automation is better than fixed in a way that

you can reprogram the equipment for a new product. But the disadvantage with programmable

automation is the time required to reprogram and change over the production equipment for

each batch of new product. In flexible automation though, the changeover of the equipment

can be done very quickly, but the variety of products is limited.

In conclusion, automation has both pros and cons. Despite all the disadvantages, I think that automation,

if used correctly can give substantial opportunities for the future. There is an opportunity to relieve

humans from repetitive, hazardous, and unpleasant labour in all forms. And there is an opportunity for

future automation technologies to provide a growing social and economic environment in which humans

can enjoy a higher standard of living and a better way of life.